Trenchless replacement and new installation of mains connection pipes

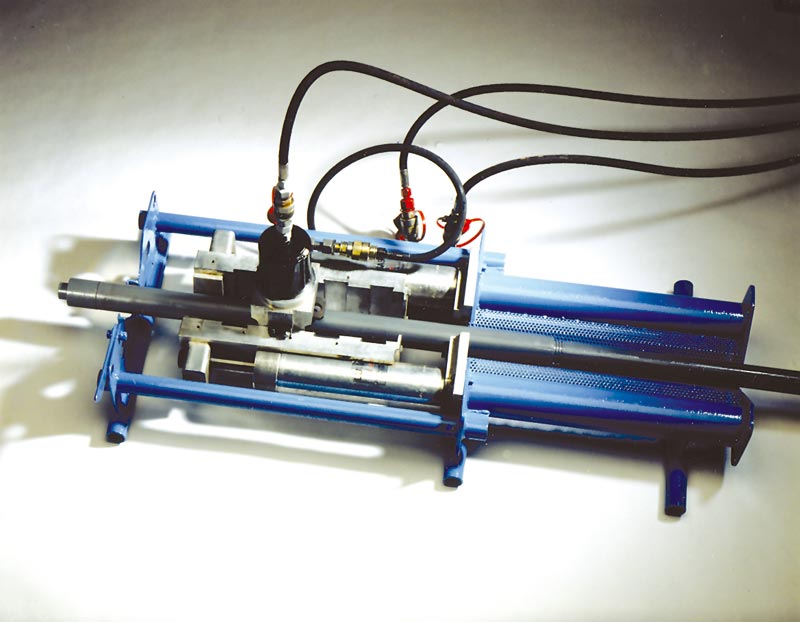

For the trenchless replacement and new installation of connection pipelines for gas and drinking water mains, compact and robust hydraulic pulling units with traction force and compressive force of up to 200 kN are available. The tried and tested equipment needs only a short set-up time. With displaceable soils, new pipes with an exterior diameter of up to 110 mm and lengths of up to 25 m are no problem.

For the following application areas of trenchless exchange and new installation of connection pipelines we have developed customized and efficient technical equipment:

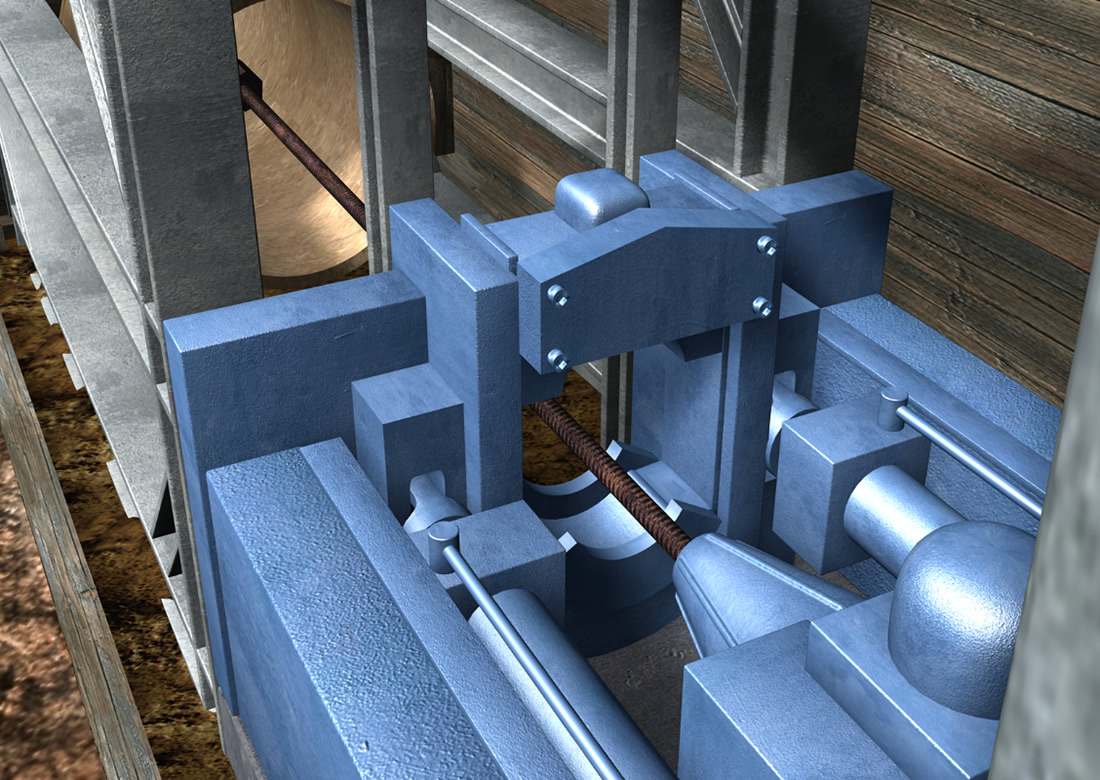

hydros®BOY:

For the exchange of mains connection pipelines made of rigid metallic materials. By using the press frame, this technology can also be used for the trenchless installation of new pipes.

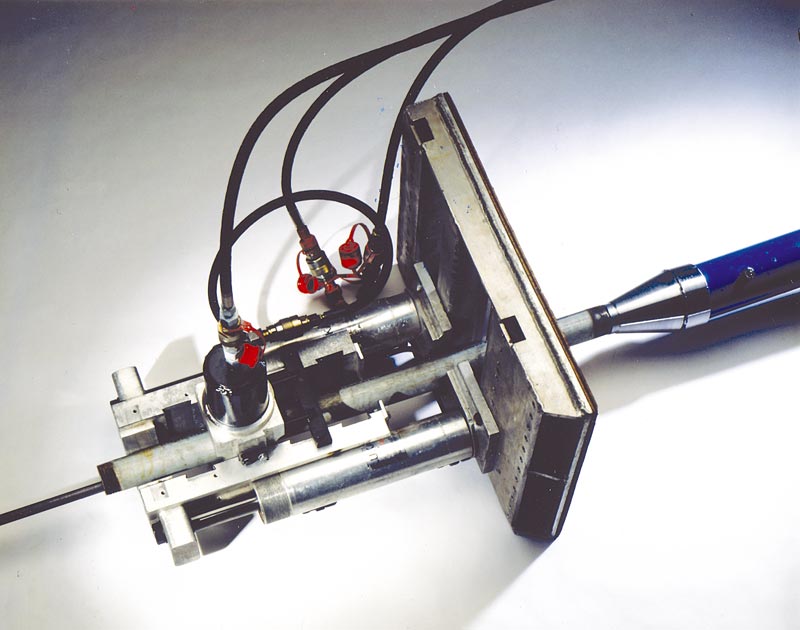

hydros®LEAD:

This innovative process, described in technical literature as a wind-up process supported by internal pressure, is used to entirely replace lead or flexible plastic drinking water connection pipes.

Of course our trenchless technology meets the requirements of the DVGW GW 325 (A) for the replacement and installation of new mains connections.